Copper Clad Aluminum Wire

550 INR/Kilograms

Product Details:

- Thickness Range from 0.12 mm to 4.50 mm

- Usage & Applications Electrical wiring, power cables, telecommunications

- Outer Diameter 0.12 mm to 4.50 mm

- Cross Dimension Depends on specification

- Features Lightweight, cost-effective, good conductivity

- Corrosion Resistant Yes

- Material Copper clad aluminum

- Click to View more

X

Copper Clad Aluminum Wire Price And Quantity

- 550 INR/Kilograms

- 100 Kilograms

Copper Clad Aluminum Wire Product Specifications

- Moderate

- ASTM Standards

- Electrical Grade

- Soft / Annealed

- Available in various sizes as per requirement

- Glossy

- Copper clad aluminum

- Yes

- 0.12 mm to 4.50 mm

- Customizable

- Aluminum core with copper coating

- Cladding and drawing

- High tensile strength

- Customizable

- Depends on specification

- 0.12 mm to 4.50 mm

- Electrical wiring, power cables, telecommunications

- Range from 0.12 mm to 4.50 mm

- Round

- Copper Clad Aluminum Wire

- Copper

- Smooth, bright finish

- Lightweight, cost-effective, good conductivity

Copper Clad Aluminum Wire Trade Information

- 1000 Kilograms Per Day

- 5 Days

Product Description

We are involved in providing our customers with copper-clad aluminium wire. Our customers greatly value our entire product line.

|

Brand |

Ganpati Engineering Industries |

|

Diameter |

5 mm |

|

Type |

Clad Wire |

|

Usage/Application |

Electrical Appliance |

|

Country of Origin |

Made in India |

|

Material |

Aluminum |

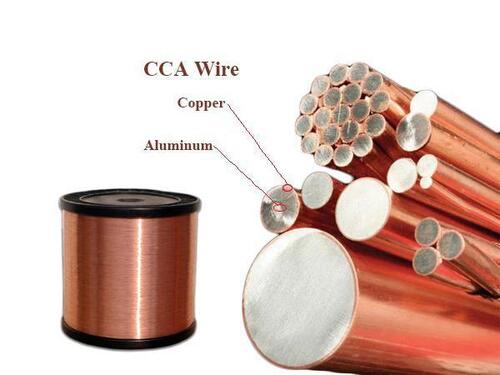

Key Attributes and Construction

Our Copper Clad Aluminum Wire offers a blend of lightweight structure and robust performance. With a density of approximately 3.2 g/cm3 and thermal handling up to 90C, its welded copper and aluminum structure ensures smooth, bright, and corrosion-resistant conductors. Available in diameters from 0.12 mm to 4.50 mm and various lengths, it complies with ASTM standards, providing strength and flexibility for both simple and complex wiring systems.

Versatile Usage Across Industries

CCA wires are widely used in electrical wiring, power transmission cables, and telecommunications due to their superior flexibility and compatibility with standard insulation types like PVC and XLPE. Their lightweight nature, being about 37% lighter than pure copper wires, makes installation easier and reduces overall project costs, without sacrificing conductivity or safety in critical infrastructure.

Efficient and Cost-Effective Solution

These wires serve as a cost-effective alternative to pure copper, delivering good conductivity (minimum 63% IACS) and high tensile strength for demanding electrical applications. The combination of a smooth, glossy surface and customizable dimensions ensures ease of use in manufacturing, export, and supply while maintaining superior performance and RoHS compliance.

FAQ's of Copper Clad Aluminum Wire:

Q: How is Copper Clad Aluminum (CCA) wire manufactured?

A: CCA wire is produced through a cladding and drawing process, where a soft/annealed aluminum core is metallurgically bonded with a layer of copper. The wire is then drawn to the desired thickness, creating a strong, flexible, and conductive product that meets ASTM standards.Q: What are the primary benefits of using CCA wire over pure copper wire?

A: CCA wire is approximately 37% lighter than pure copper wire, offering cost savings in material and transportation without significantly compromising conductivity. Its high tensile strength, moderate hardness, and corrosion-resistant properties also ensure reliable performance in electrical applications.Q: When should I choose CCA wire for my project?

A: CCA wire is ideal for projects where weight reduction, cost efficiency, good electrical conductivity, and RoHS compliance are important. It's particularly suitable for electrical wiring, power cables, and telecommunications in residential, commercial, and industrial settings.Q: Where can Copper Clad Aluminum Wire be used?

A: This wire is suitable for a range of applications, including electrical wiring, power transmission, telecommunications, and cable assemblies. Its compatibility with various insulation materials such as PVC and XLPE makes it versatile for both indoor and outdoor installations.Q: What insulation types are compatible with CCA wire?

A: CCA wire is suitable for standard insulation types like PVC, XLPE, and other commonly used materials, ensuring safe and efficient electrical insulation in various construction and engineering projects.Q: How does the CCA wire's copper thickness affect performance?

A: The copper thickness-ranging from 8% to 40% of the conductor diameter-affects the wire's conductivity and surface properties. Higher copper thickness enhances conductivity and surface corrosion resistance, making it adaptable for different electrical demands.Q: What is the minimum order quantity for CCA wire?

A: The minimum order quantity for CCA wire is flexible and can be customized according to the client's needs, allowing for tailored supply whether for small, specialized requirements or large-scale projects.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese